Telefon: +49 (0) 6152 - 98 01 - 5

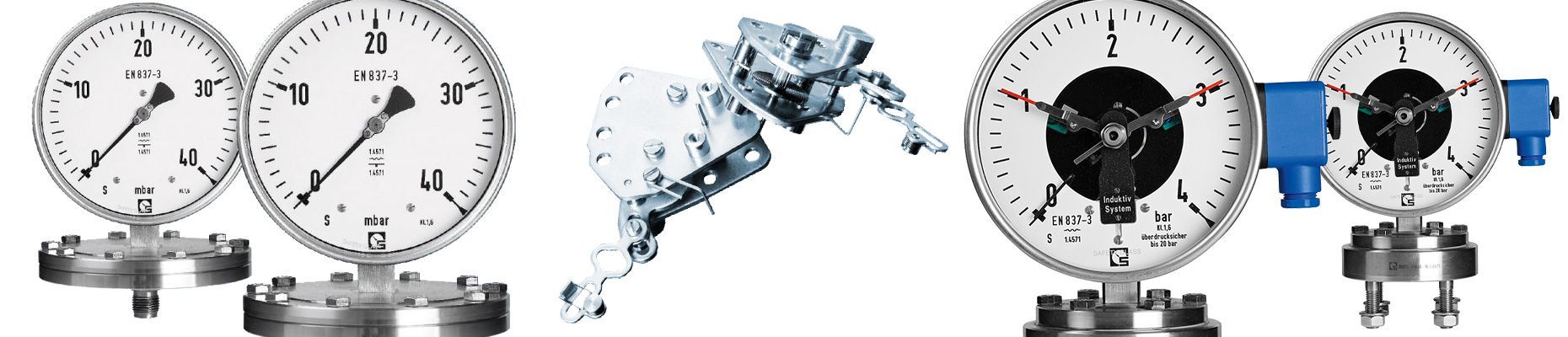

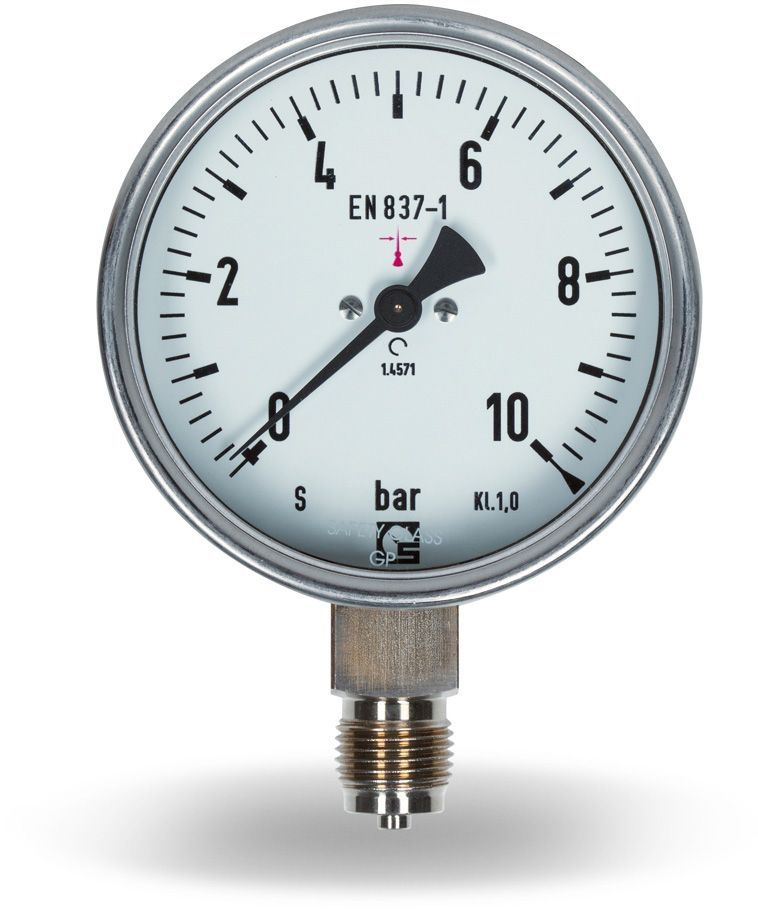

Bourdon tube pressure gauges

Bourdon tube pressure gauges are the most widely used pressure gauges.

- They are most frequently used in the food and chemical industries and are suitable for measuring liquid or gaseous media.

- The advantages of Bourdon tube pressure gauges are their comparatively low cost, simple design, insensitivity to high pressures and high measuring accuracy.

The functional principle is based on a circularly bent tube, which is firmly connected to a connection piece at one end and closed with an end piece at the other end. If the interior of the Bourdon tube is subjected to overpressure, it expands outwards; in the case of negative pressure, it contracts inwards.

This movement of the Bourdon tube end piece is the measure of the pressure to be measured and is transmitted to the pinion of the pointer mechanism via a toothed segment, thereby converting it into a rotary movement and indicating it on the scale by means of a pointer.

What makes the Bourdon tube pressure gauges from Schmierer so special?

- With Bourdon tube pressure gauges from Schmierer, you are better advised in the long term. We provide you with high-quality, customised devices, specially designed for your application.

- This means you are well equipped for many years of use. Thanks to the high-quality design, you save on replacement and purchasing costs and have to keep fewer devices in stock due to the long-term design.

What else we do for you!

- We produce Bourdon tube pressure gauges with a wide range of measuring ranges, measuring units, process connections and in various nominal sizes and designs.

- For critical applications, we also offer liquid-filled Bourdon tube pressure gauges (glycerine or insulating oil filling).

- In the event of strong vibration, this causes damping which prevents pointer flutter, thus ensuring good readability and also protecting the individual parts from damage.

- It also prevents freezing at low temperatures.

MANODAMP@ axle damping system - the cheaper alternative

Our "MANODAMP®" axle damping system offers the same advantages, but at a lower price and without the risk of liquid leakage. Devices with shaft damping are therefore the best choice for applications with high hygiene requirements, such as in the pharmaceutical industry.

Interested? Then get your offer here quickly!

Simply use the following form! We will get back to you as soon as possible.