Telefon: +49 (0) 6152 - 98 01 - 5

Pressure / differential pressure transmitters

- Reliable and high-precision pressure and differential pressure transmitters are part of our extensive product portfolio.

- We offer devices with maximum long-term stability with various electrical interfaces, process connections and housing types for your specific application.

- A pressure transmitter (often also referred to as a pressure transducer) is a pressure sensor mounted in a housing that converts a pressure signal into an electrical output signal.

- In the case of differential pressure transmitters, pressure differences are detected and converted accordingly by the sensor.

- Pressure and differential pressure transmitters are used in numerous industries, including pressure measurement technology, process technology, process engineering and the pharmaceutical industry.

- Differential pressure transmitters are used in particular for filter and pump monitoring as well as level and flow measurements.

- They are suitable for use in appliances as well as for outdoor use under harsh environmental conditions. Depending on the area of application, the devices differ in terms of technology, design and performance.

- We also realise the attachment of various diaphragm seals to pressure and differential pressure transmitters, including to devices provided by you.

- The repair of your pressure transmitters in use is also part of our range of services. This is often much cheaper than buying a new one (savings of up to 70%) and also protects the environment. Send us your devices and receive a free repair quote.

Diaphragm seals

Diaphragm seals & repairs

- Pressure measurement is an important task in industries where thermal processes take place. A variety of instruments, such as the Bourdon tube, are used for this task and there are numerous cases where pressure measurement is made difficult due to the influence of various factors on the measuring device. This is where diaphragm seals are used. Diaphragm seals are used in situations where it is necessary to isolate the pressure sensor from the process medium.

What are diaphragm seals?

- Diaphragm seals are a safety device that keeps potentially harmful process media away from pressure measuring devices, transmitters and pressure switches. The pressure is applied to the flexible diaphragm instead of the surface of the pressure sensor and then transmitted hydraulically to the device via the filling fluid. A diaphragm seal unit has no effect on the performance of the device if it is placed and filled correctly.

- Diaphragm seals have the task of separating the pressure measuring device from the process medium. They are often used for the most difficult measuring processes. Examples of such difficult situations are extreme ambient conditions, when it is difficult to establish a process connection to the measuring device, when the medium to be measured is corrosive, viscous, sticky or easily solidified or when the process is chemically incompatible with the material of the instrument.

Types of diaphragm seals

Diaphragm seals can be divided into the following categories based on the areas of application:

- Inline diaphragm seal

- This type of diaphragm seal is used to ensure the passage of liquids and is used in various connection types.

- Screw-in diaphragm seal

- Screw-in diaphragm seals are intended for direct process connection with a thread. These are used with pressure gauges with pressure switches and transmitters and can be connected to these via capillary lines.

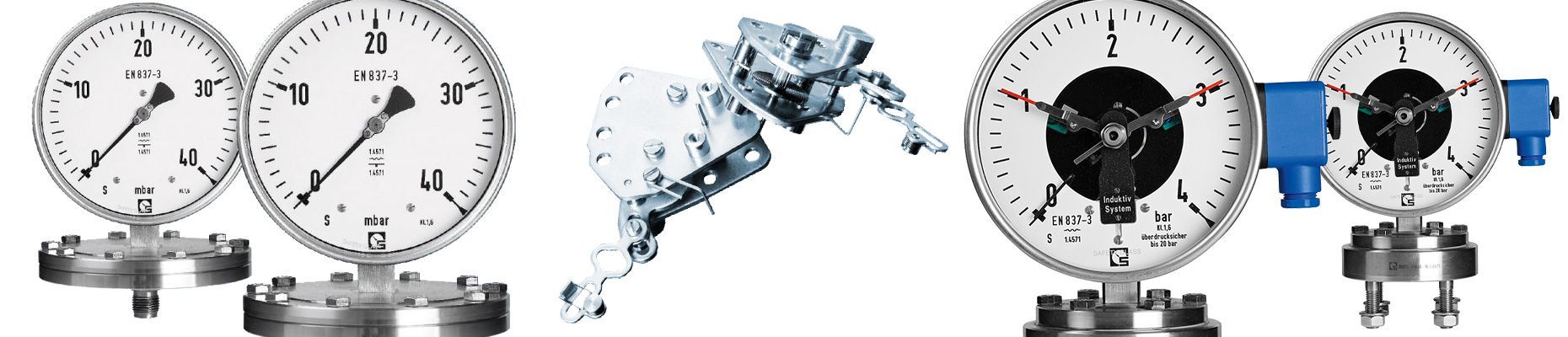

Flange diaphragm seal

- A flange diaphragm seal is designed for direct mounting on pipes, tanks and other standard flange connections. Thanks to their flexibility, they can be mounted directly on various pressure gauges and switches.

- Hygienic diaphragm seal

- Hygienic diaphragm seals are specially manufactured for the food and pharmaceutical industries, where it is particularly important to prevent the growth of bacteria.

Where can diaphragm seals be used?

Some of the areas of application for diaphragm seals are listed below:

- Diaphragm seals are generally used where it is important to protect pressure gauges and pressure transmitters from the measured medium or from heat.

- All diaphragm seals can also be made from duplex steels or other types of stainless steel.

- Diaphragm seals can be used for Bourdon tube pressure gauges, pressure switches, pressure transmitters and differential pressure gauges or transmitters.

Diaphragm seals can be used in situations where corrosive process fluids are present.

- Diaphragm seals can be used in situations where the process fluid, e.g. slurry, sludge or similar material, has a high viscosity or contains other materials that could contaminate or damage conventional pressure monitoring devices.

- Diaphragm seals can also be used in situations where the process fluid may freeze or solidify, potentially causing the device to malfunction or impair its ability to obtain an accurate pressure measurement or send a signal.

Interested? Then get your offer here quickly!

Simply use the following form! We will get back to you as soon as possible.