Phone: +49 (0) 6152 - 98 01 - 5

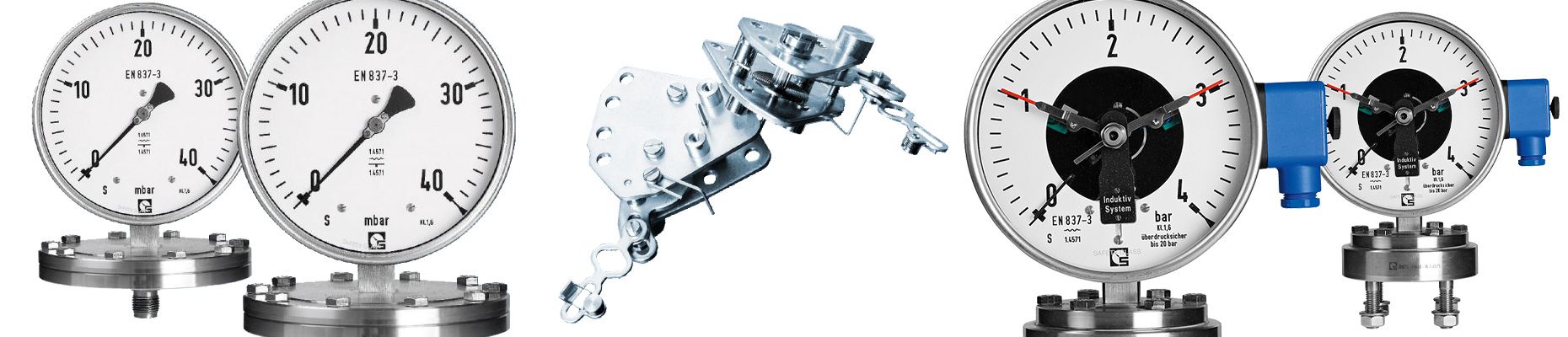

Test pressure gauges

Function of a test pressure gauge

The measuring function is the same as with a normal bourdon-tube gauge. A circularly bended tube is on the one side connected to a socket and on other side it is closed. When there is overpressure inside the bourdon tube it stretches itself to the outside, if there is negative pressure the bourdon tube contracts inwards. This movement of the ending of the bourdon tube is a measure for the incoming pressure and is carried over to a gear segment and then onto the gear of the movement.

Application purposes

With a bourdon tube pressure gauge you can measure fluids, gases and steams with a positive pressure up to 1000 bar and negative pressure up to 1 bar. For the test pressure gauges we will be using special movements and bourdon tubes. The standard accuracy of the test pressure gauges is between ± 0,6% of the upper range value.. We also offer special versions with an accuracy of ± 0,25% and ± 0,1% of the upper range value.

Test Pressure Gauge F 160

- diameter 160 mm

- EN 837-1

- class 0,6

- bourdon tube made of special bronze, connection made of brass

- bayonet lock case made of stainless steel

- threading 1/2″ BSP

Test Pressure Gauge FU 160

- diameter 160 mm

- EN 837-1

- class 0,6

- bourdon tube and connection made of stainless steel

- bayonet lock case made of stainless steel

- threading 1/2″ BSP

Test Pressure Gauge F 250

- diameter 250 mm

- EN 837-1

- class 0,6

- bourdon tube made of special bronze, connection made of brass

- bayonet lock case made of stainless steel

- threading 1/2″ BSP

Test Pressure Gauge FU 250

- diameter 250 mm

- EN 837-1

- class 0,6

- bourdon tube and connection made of stainless steel

- bayonet lock case made of stainless steel

- threading 1/2″ BSP